- Overview

- Product Description

- Detailed Photos

- Our Advantages

- Product Parameters

- Related Products

- Company Profile

Basic Info.

Packaging & Delivery

Product Description

HCS17B Horizontal Cement Silo is designed based on 20ft container size. It can be stored in standard container directly. Save shipping costs. More container silos can be stacked together to work.

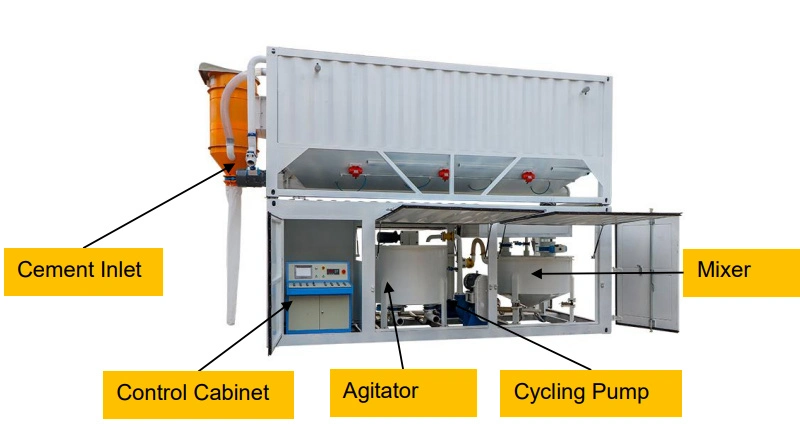

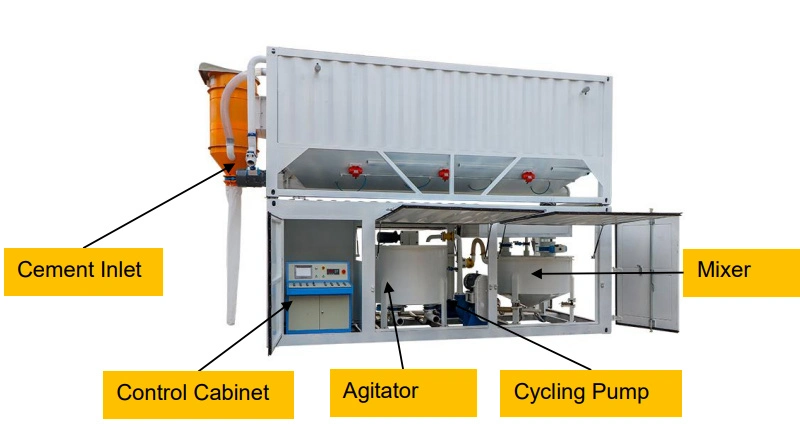

LMA20 Automatic Mixing Plant is making reference to, was mainly conceived in order to obtain, through a high turbulence mixing of water and cement powder, a cement mixture (cement grout), or, by using water and bentonite powder, a bentonite sully for plastic muds. Also, the preparation of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid component (for every screw conveyor).

The cement mixture or the bentonite sully is then transferred to the other units, according with the type of foreseen geotechnical machines.

Mixing Plant can be worked under Container Silo. 20ft and 40ft container silos both are provided.

CEMENT SILO

CEMENT SILO

- Upper recalling dipstick(2) and lower recalling dipstick(2)

- Dust collector(1)

- Pressure relief valve(2)

- OLI-WOLONG Vibrator(6)

Automatic Mixing Plant

Automatic Mixing Plant

- High-speed Colloidal Grout Mixer

- Main pipeline valves are all pneumatic valves

- Mixture, cycling pump and agitator have automatic cleaning function

- Cement can be added by cement silo or screw feeder automatically

- The preparing of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid components

- Two modes of operation:fully automatic mode and manual mode

- Easy to operate and maintain

- Up to 5mm particle size

- Equipped with some ceiling lamps, for illuminating the different working areas.

- Can be placed directly in the 20ft cabinet

| Specification : | |||

| 1. Two modes of operation: fully automatic mode and manual mode. 2. Automatic cleaning system. 3. The preparation of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid component. 4. Can be placed directly in the 40ft cabinet. | |||

| HCS17B Cement Silo | |||

| Volume | 17m³ | Conveying | 40t/h |

| Inlet Dia. | 100mm | Outlet Dia. | 273mm |

| Power | 18.5Kw | Power supply | 380V,50Hz |

| LMA20 Mixing Plant | |||

| Mixer | Agitator | ||

| Volume | 1000L | Volume | 1100L |

| Flow | 1200L/min | Speed | 25r/min |

| Max. output | 20m³/h | Level sensor | Damped rotation controller |

| Power | 15Kw | Power | 3.0Kw |

| Air supply system | Water supply system | ||

| Flow | 300L/min | Water tank volume | 750L |

| Pressure | 0.8MPa | Flow@lift | 9.03L/[email protected] |

| Power | 3.0Kw | Power | 3.0Kw |

| Power supply | 380V, 50Hz | ||

| Date: 1. All data are tested by water. 2. We can customize products according to your requirements. | |||

LGP114/500-120D High-pressure Jet Grout Pump

High Quality Electric Grout Mixer Pump Price

Helpful LinksTo browse more products, please click here

For our catalogs, please click here

For instant communication, please click here